Page 57 - MARINE ROPES CATALOGUE - LANCELIN

P. 57

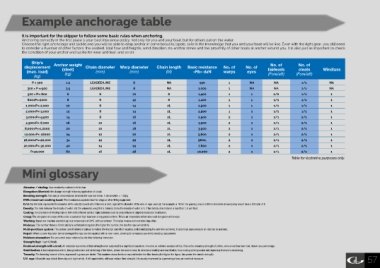

Example anchorage table

It is important for the skipper to follow some basic rules when anchoring.

Anchoring correctly in the first place is your best insurance policy: not only for you and your boat, but for others out on the water.

Choose the right anchorage and tackle and you will be able to drop anchor in some beautiful spots, safe in the knowledge that you and your boat will be fine. Even with the right gear, you still need

to consider a number of other factors: the seabed, tidal flow and heights, wind direction, no-anchor zones and the proximity of other boats at anchor around you. It is also just as important to check

the condition of your anchor and tackle for wear and tear, and so on.

Ship’s

No. of

displacement Anchor weight Chain diameter Warp diameter Chain length Basic resistance No. of No. of fairleads No. of Windlass

(steel)

cleats

(max. load) (kg) (mm) (mm) (M) «Rb» daN warps eyes (Fore/aft) (Fore/aft)

(kg)

P < 300 1.5 LEADED LINE 6 NA 550 1 NA NA 1/1 NA

300 < P <=500 3.5 LEADED LINE 8 NA 1,000 1 NA NA 1/1 NA

500 < P<=800 6 6 10 8 1,400 1 1 1/0 1/1 1

800<P<=1000 8 6 12 8 1,400 1 1 1/1 1/1 1

1,000<P<=2,000 10 8 14 2L 2,500 1 1 1/1 1/1 1

2,000<P<=3,000 12 8 14 2L 2,500 1 1 1/1 1/1 1

3,000<P<=4,500 14 8 16 2L 2,500 2 1 2/1 2/1 1

4,500<P<=8,000 16 10 16 2L 3,900 2 1 2/1 2/1 1

8,000<P<=1,2000 20 10 18 2L 3,900 2 1 2/1 2/1 1

12,000<P<=16000 24 12 20 2L 5,600 2 1 2/1 2/1 1

16,000<P<=20,000 34 12 22 2L 5600, 2 1 2/1 2/1 1

20,000<P<=30,000 40 14 24 2L 7,600 2 1 2/1 2/1 1

P>30,000 60 16 28 2L 10,000 2 1 2/1 2/1 1

Table for ilustrative purposes only.

Mini glossary

Abrasion / chafing: How resistant a material is to friction.

Elongation (Stretch): the change in length following application of a load.

Breaking strength: The load (in decanewtons) at which the rope will break. 1 decanewton = 1.02kg

MWL (maximum working load): The maximum acceptable load for slings or other lifting equipment.

D/d: the D/d ratio represents the diameter of the axis (D) around which the line is bent, against the diameter of the wire or rope used (d). For example: a 10mm line passing around a 50mm diameter sheave/pulley would have a D/d ratio of 5.

Density: The ratio between the density of water and the volumetric weight of a material. Since the density of water is 1, if the density of a material is less than 1, it will float.

Coating: the procedure of treating rope or fibre with different solid or liquid solutions such as polyurethane to improve resistance to abrasion.

Creep: The elongation of a rope while under a sustained high load over a long period of time. This is an irreversible deformation and elongation of the rope.

Washing: Ropes are machine washable up to a temperature of 30°C, without softener. This helps remove salt and other impurities.

Modulus: This number shows a fibre’s ability to withstand elongation (the higher the number, the less the rope will stretch).

Multi-purchase system: This system uses thimbles or pulleys to reduce the traction and effort required, whilst multiplying the end force achieved. It also helps ease pressure on clutches or jammers.

Repair: Where a cover has been torn or damaged the rope can be repaired with an over cover, allowing for temporary use whilst awaiting replacement.

Moisture absorption: The amount of water retained by the fibre following immersion.

Strength (kg): 1 kgf=0.98daN.

Residual strength with a knot: All materials lose some of their strength when subjected to a significant curvature. A knot is an extreme example of this. This is the remaining strength of a fibre, once a knot has been tied, shown as a percentage.

Stabilisation: A thermal process which, through retraction and stretching of the fibres, allows the rope to keep its directional stability and stay flexible, thus making splicing easier and improving the rope’s weathering.

Tenacity: The breaking force of a fibre, expressed in grams per denier. This number shows the force required before the fibre breaks (the higher the figure, the greater the tensile strength).

57

U.V. rays: Ultraviolet rays attack fibres day and night which, if left unprotected, will soon reduce their strength. It is usually expressed as a percentage loss per month of exposure.